The cultivation of Theobroma cacao and production of cocoa beans are the first and most important steps towards creating cocoa ingredients and chocolate.

Unveiling the art and science behind sustainable cocoa cultivation

The cultivation of Theobroma cacao and production of cocoa beans are the first and most important steps towards creating cocoa ingredients and chocolate.

Today, cocoa trees are productive in three to four years after planting, while in the past, six to seven years was common. When the cocoa tree reaches its bearing age, flowers and fruits begin to appear in modest amounts. These fruits grow directly from the trunk of the tree and the thicker branches.

While there may be several thousand flowers on a mature tree, only a small number develop into fruits or pods. These take some six months to grow from a fertilized flower, and measure 10-15 cm around the center and are 15-25 cm long. The pod contains some 40 seeds or beans.

After fermentation and drying, one pod produces around 40g of beans, one bean typically weighing around 1g.

Once ripe the pods are mostly harvested by hand using long-handled cutting tools and then broken open to reveal the beans and the white pulp surrounding them. Beans are then extracted and directly subjected to fermentation.

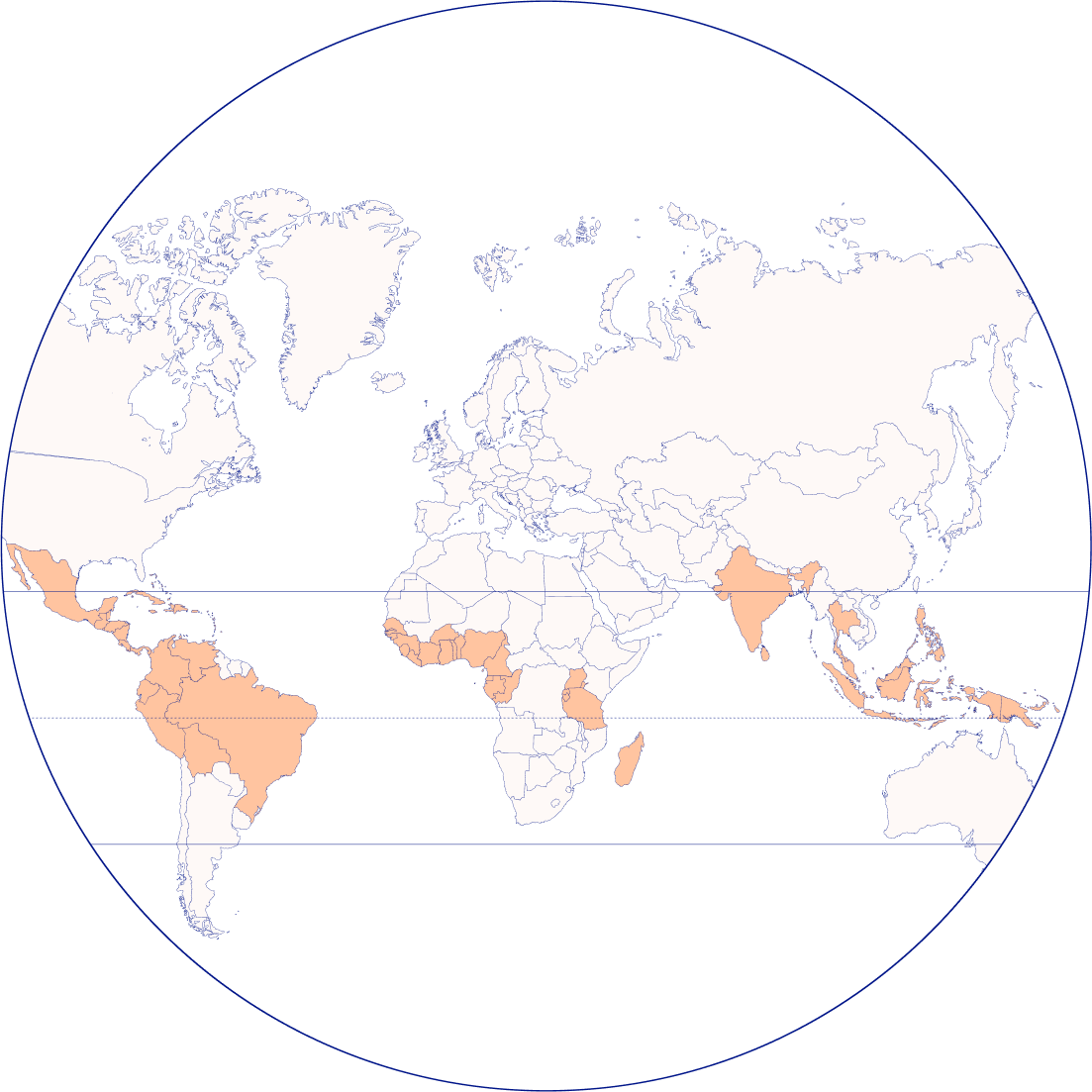

The equatorial band between the Tropics of Cancer and Capricorn. ofi’s Cocoa bean sourcing origins

Temperature

18–21° C

Rainfall - MM

2,000

Years to first fruit

3

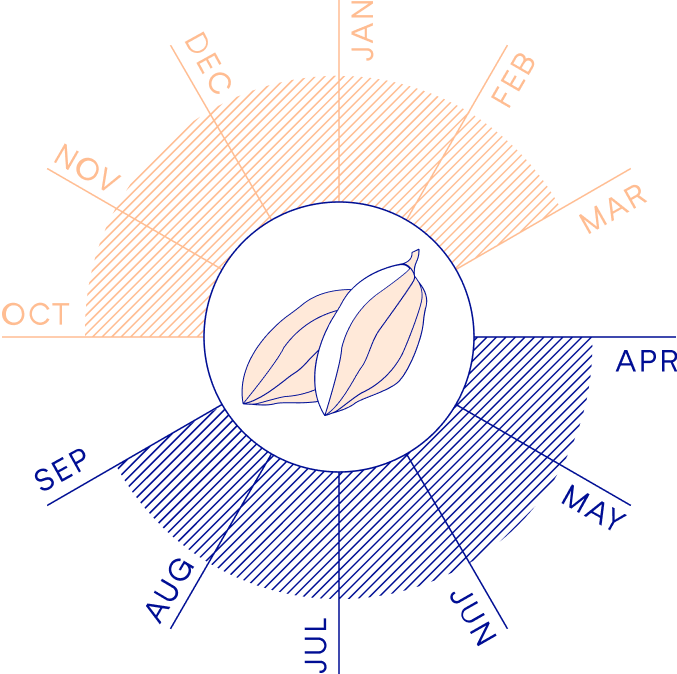

The main crop is harvested between October - March each year*

The mid crop is the smallest harvest that occurs between April - September each year*

* Season period in West Africa

85%

Dominant variety, easier to grow, producing more beans with high fat content and more flavor.

10%

Cross of Criollo and Forastero with strong, fruity flavor

5%

Rare variety with unique flavor

Fermentation

Heap fermentation 4-7 days

The traditional process in West Africa, the world’s largest cocoa growing area, is simple: farmers place the pulp-covered beans on the ground, cover them with layers of leaves (often banana) and allow the heap to remain for four to seven days, depending on the variety of the bean. It is preferable to mix the heap every two days so that the bean mix ferments evenly. The fermentation is critical for the future development of color and flavor of the cocoa, although there are still many unknowns as to the exact processes occurring.

Heap fermentation 4-7 days

A more industrial fermentation uses three to five stepwise-positioned boxes: the highest box is filled with pulp-covered beans, and after one to two days the content is mixed and transferred to the next lower box, a process which is repeated until the lowest box is reached. In four to six days, this box fermentation can reach the result of the traditional heap process.

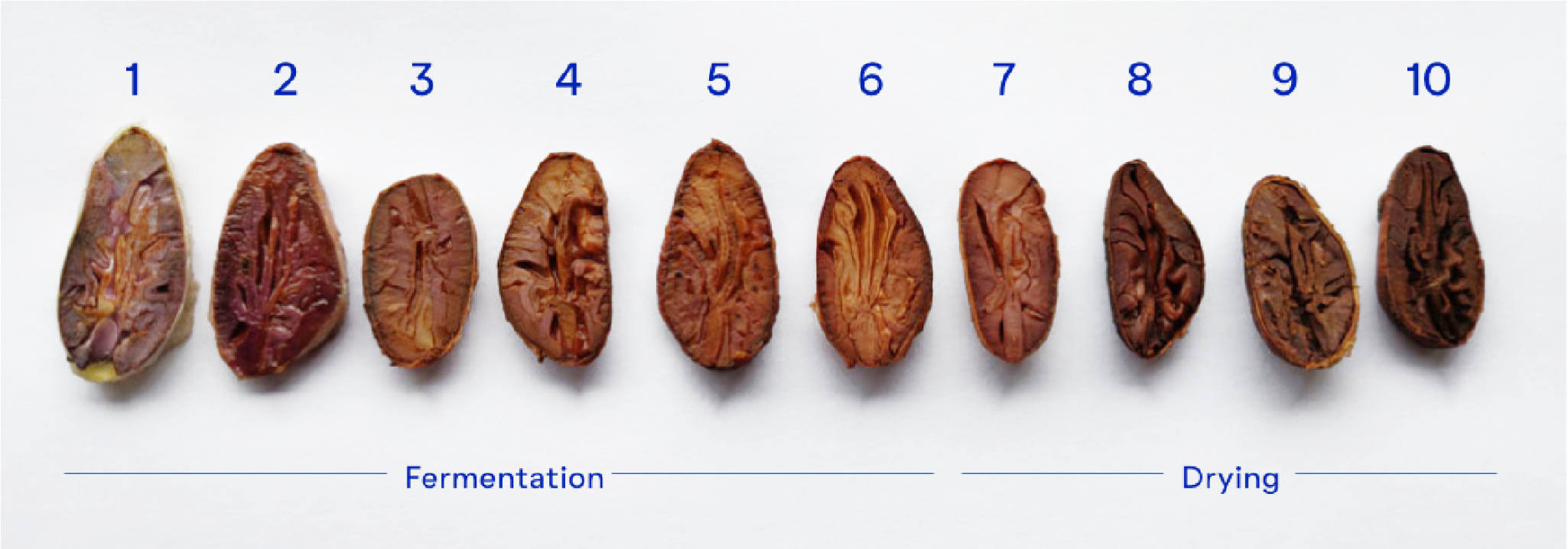

This picture shows the changing in color as the fermentation and drying process proceeds from days 1 to 10.

After the fermentation process is completed, the cocoa beans have to be dried to reduce moisture content to around 8%.

Optimal technique worldwide - 1 week

In Africa the traditional method is to spread the beans out on mats or trays in the open air to dry in the sun for about one week.

Technique of raining during harvest - 1 week

Because of the high rainfall and cloud cover in Brazil, Cameroon and Papua New Guinea, other techniques have had to be developed including indoor drying, solar drying and mechanical drying.

Once the cocoa beans are fermented and dried they can be assessed for quality. The quality of beans is assessed under various headings:

Bean Count (defined as the number of beans that make up 100g)

Moisture content

Defects (including mouldy, slaty, violet or flat beans)

Foreign materials (such as infestation, grit or sticks)

Free fatty acids

And for some origins, heavy metal content is also considered. The bean cut test is used to evaluate defects and the degree of fermentation. An example of the different fermentation related defects can be seen below.

Another key criterion is flavor. An expert panel grades a consignment, seeking to identify flavor profiles and off-flavors. These depend on the type of bean, its origin and its handling. Off-flavors often come from moulds; smoky taints may come about during drying, due to the use of fires placed underneath drying mats in some regions; acidic off-flavors are due to excessive acid created during fermentation or improper drying.

Farmers send their pre-processed beans to local co-operatives.

The co-operative then send the beans on to receiving stations where they are consolidated and tested for quality and, then shipped around the world.

When the cocoa beans are grown on very small farms, the collection, grading and financing of the crop can be rather complex. At the co-operative or buying station, a farmer’s crop is weighed, inspected and paid for at the current market (or government-set) price. Price discounts/premiums can also be made for poor/good quality. From the buying stations, the cocoa beans are collected and finally shipped to the nearest port of embarkation or delivered to local processing plants.

Sales are then made to licensed traders and cocoa merchants or directly to cocoa processors. Cocoa brokers can be intermediaries who have expertise on crops and trade and who advise and act for both buyers and sellers. Major destinations include Amsterdam, Hamburg and Philadelphia. Amsterdam receives about 20% of the world crop.

Learn more about black cocoa powder for baked goods and food manufacturing

How is the cocoa bean transformed into cocoa ingredients?

How does cocoa powder behave as an ingredient?