About Black Cocoa Powder

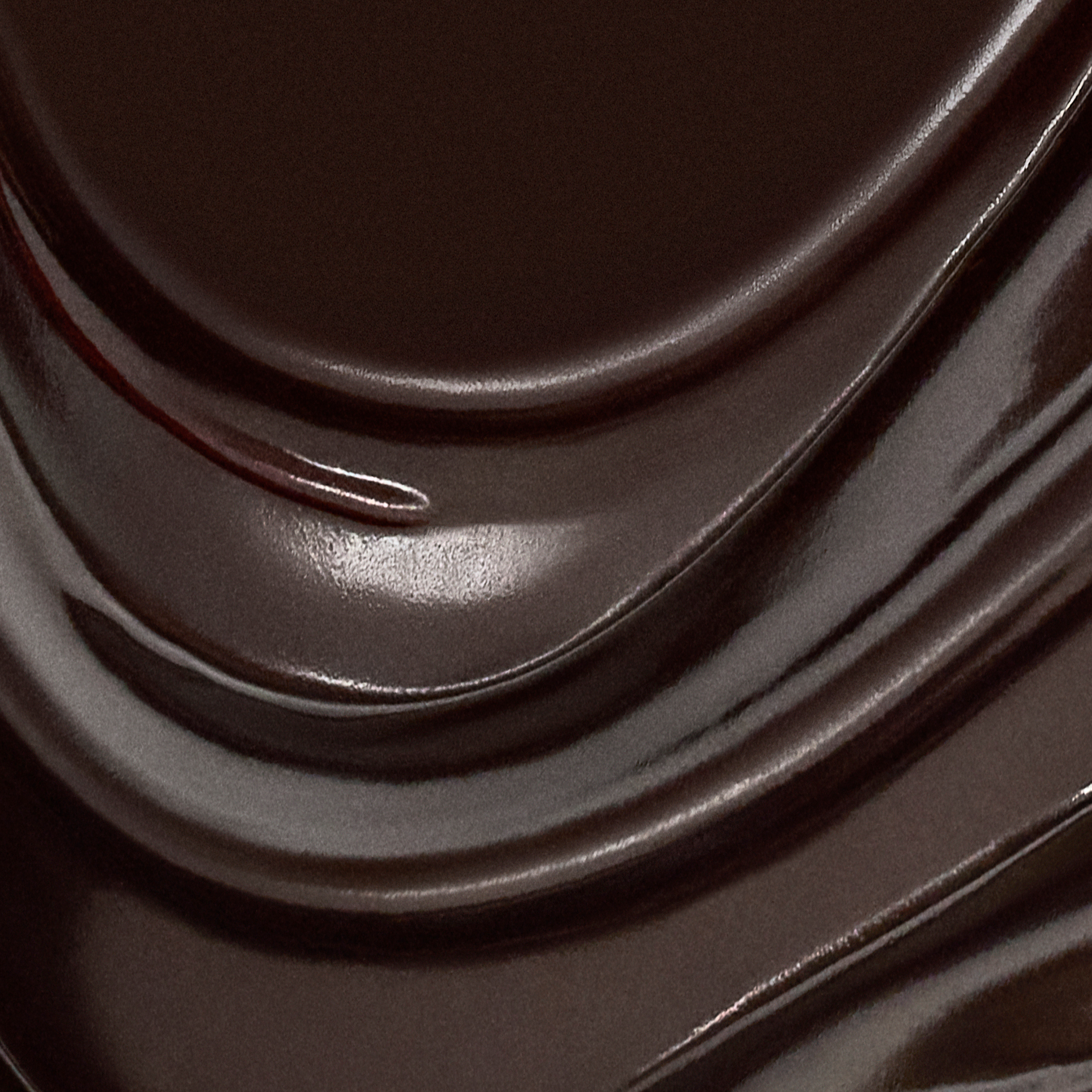

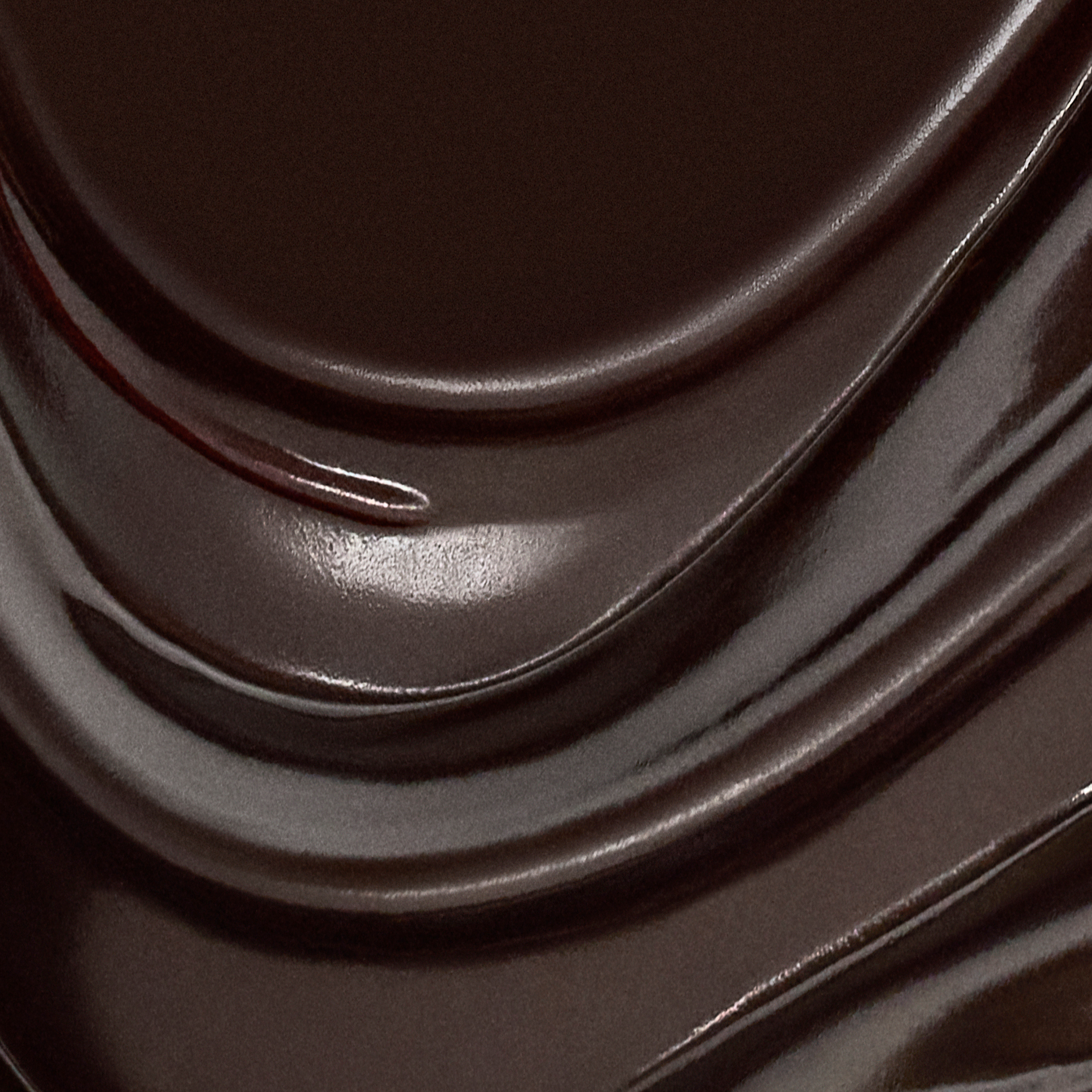

Black cocoa powder, a unique and versatile ingredient, has gained significant attention in the food manufacturing industry. Black cocoa powder represents the pinnacle of cocoa alkalization technology, delivering consistent black color essential for modern food manufacturing. Known for its deep color and rich flavor, it is a favorite among bakers and chocolate enthusiasts as well as food manufacturers and confectionery producers.

What is Black Cocoa Powder?

Black cocoa powder is derived from the beans of the Theobroma cacao tree, which undergoes a specific processing method that distinguishes it from cocoa powder. The cacao nibs undergo a Dutch processing method, which alkalizes the cocoa and gives it a darker color and a more intense flavor profile.

Characteristics of Black Cocoa Powder

Black cocoa powder is characterized by its dark color, which can range from deep brown to almost black.

However, the challenge when producing a very dark cocoa powder is achieving a desirable flavor that's free of unwanted alkali notes or off-flavors. The black cocoa powders available in the market are often lacking that cocoa flavor that is loved by many and are often plagued by strong off-notes that may feel unpleasant to the palate.

deZaan black cocoa powders are known for its clean, strong cocoa flavor without off-notes because customers will only repurchase a product if it tastes great so the flavor is an important characteristic of a black cocoa powder. Baking products, chocolate and compounds are applications where deZaan black powders can guarantee a consistent dark color which goes seamless with a clean and strong cocoa flavor. Black cocoa powders are also used in combination with other cocoa powders to achieve a darker and consistent colored product in certain recipes like desserts or ice creams.

The Production Process

The journey of black cocoa powder begins with the same careful cultivation and processing steps as all cocoa products. Farmers harvest the ripe pods, which contain the cocoa beans. The beans are then fermented, dried, and roasted. These are standard steps that develop the fundamental flavor profile of all cocoa powders.

What makes black cocoa powder black is the intensive alkalization process (Dutch processing) that follows these standard steps. This is where black cocoa diverges from regular cocoa powder production.

Step 1: Fermentation

This step is essential for developing the beans' flavor. The beans are placed in heaps and covered with banana leaves for several days.

Step 2: Drying

After fermentation, the beans are spread out to dry in the sun, which can take up to a week.

Step 3: Alkalization (Dutch Processing)

This is the critical step that creates black cocoa powder. The cocoa undergoes ultra-alkalization treatment with food-grade alkaline solutions (potassium or sodium carbonates), raising the pH to 8.0-8.8. This intensive treatment darkens the color from brown to rich black while mellowing the flavor and improving solubility.

Step 4: Roasting

The dried beans are roasted at high temperatures, which enhances their flavor and color.

Step 5: Grinding

The roasted beans are ground and pressed to separate cocoa butter from cocoa solids, creating cocoa mass or cocoa cake.

Step 6: Final Grinding

The alkalized cocoa is ground into the fine black cocoa powder used in manufacturing.

Step 1: Fermentation

This step is essential for developing the beans' flavor. The beans are placed in heaps and covered with banana leaves for several days.

Industrial Applications of Black Cocoa Powder

Sandwich cookie production

Usage rate: 4-8% in cookie dough

Applications: Cream-filled sandwich cookies, cookie ice cream sandwiches, seasonal black-themed cookies

Advantage: Achieves signature black color without impacting texture

Premium bakery products

Usage rate: 5-10% replacement of standard cocoa

Applications: Dark chocolate cakes, brownies, specialty breads

Advantage: Maintains color stability through 180°C+ baking temperatures

Confectionery manufacturing

Usage rate: 8-15% in formulation

Applications: Compound coatings, dark chocolate analogues

Advantage: Cost-effective color enhancement without bitter notes

Dairy & beverage applications

Usage rate: 1-3% for color enhancement

Applications: UHT chocolate milk, ice cream bases

Advantage: Excellent suspension properties in liquid systems

Sandwich cookie production

Usage rate: 4-8% in cookie dough

Applications: Cream-filled sandwich cookies, cookie ice cream sandwiches, seasonal black-themed cookies

Advantage: Achieves signature black color without impacting texture

Bakery Manufacturing

Industrial bakery operations leverage black cocoa powder for high-volume production of differentiated products. Key applications include sandwich cookies (4-8% inclusion), dark-variant product lines, and seasonal SKUs requiring dramatic visual impact. The powder's pH stability ensures predictable leavening performance across automated production lines, while its low fat content (10-12%) simplifies dough rheology management. Major bakery manufacturers report 15-20% reduction in total cocoa usage when combining black cocoa with standard grades for color-optimized formulations.

Chocolate Confectionery Production

Black cocoa powder serves critical functions in industrial chocolate and compound coating systems. At 8-15% inclusion rates, manufacturers achieve deep color targets without the bitter notes associated with high-percentage natural cocoa. This enables cost-effective production of dark chocolate analogues and premium-positioned confections. The powder's consistent particle size (99.5% through 75 micron) ensures smooth mouthfeel in molded products and uniform dispersion in compound systems. Additionally, its neutral flavor allows for precise flavor profiling through complementary ingredients.

Beverage and Dairy Applications

In liquid systems, black cocoa powder demonstrates superior functionality for industrial beverage and dairy applications. UHT processing compatibility and excellent suspension properties make it ideal for chocolate milk, RTD beverages, and ice cream bases at 1-3% usage rates. The powder's fine particle size prevents sedimentation in extended shelf-life products, while its intense color enables significant reductions in total cocoa requirements. Dairy manufacturers particularly value its performance in low-fat formulations where color impact is critical for consumer acceptance.

The Future of Black Cocoa Powder

As food manufacturers seek ingredients that deliver dramatic visual impact and functional performance, the demand for black cocoa powder continues to grow.

The multifunctional nature of black cocoa powder - delivering both color impact and consistent processing performance - allows producers to innovate across categories from bakery to beverages while optimizing formulation costs.

This trend presents opportunities for food manufacturers to differentiate premium product lines and create visually distinctive product variants that stand out in competitive retail environments.

D11EB

Dutched Kakaopulver

Kakaobutter 10-12%pH-Bereich 8.2-8.8

Extra dunkle Farbe, kräftiger Geschmack.

Exceptional Quality. Smart Economics. Proven Reliability.

Partner with deZaan for black and dark cocoa powders that enable bold innovation and distinctive product development. Achieve remarkable sensory impact while maintaining cost efficiency and value optimization. Count on deZaan comprehensive support from technical formulation assistance and supply chain transparency to customized solutions for your specific production needs.

![Cocoa Cultivation Farmer]()

![Cocoa Cultivation Farmer]()

Cocoa Cultivation

Alle anzeigen Cocoa Cultivation

![3]()

![3]()

Cocoa Processing

Alle anzeigen Cocoa Processing

![Cocoa In Application]()

![Cocoa In Application]()

Cocoa in Application

Alle anzeigen Cocoa in Application