Pre-Cleaning

Initially, the cocoa beans are properly screened, and foreign matter are removed.

From bean to bliss: Exploring the journey of cocoa production

The top priority in cocoa production is obtaining the highest-quality cocoa beans. At deZaan we believe that the integrity of cocoa beans plays a significant role in determining the ultimate characteristic of the end products.

ofi’s global network includes a team of expert assessors that examine the quality and select the best types of cocoa beans from all around the world. To ensure that our factories receive consistent quality and quantity, our cocoa from different countries and regions are often blended together before they enter the plant.

Once the cocoa beans arrive at the deZaan facilities, they are carefully processed to transform them into different superb cocoa ingredients.

Initially, the cocoa beans are properly screened, and foreign matter are removed.

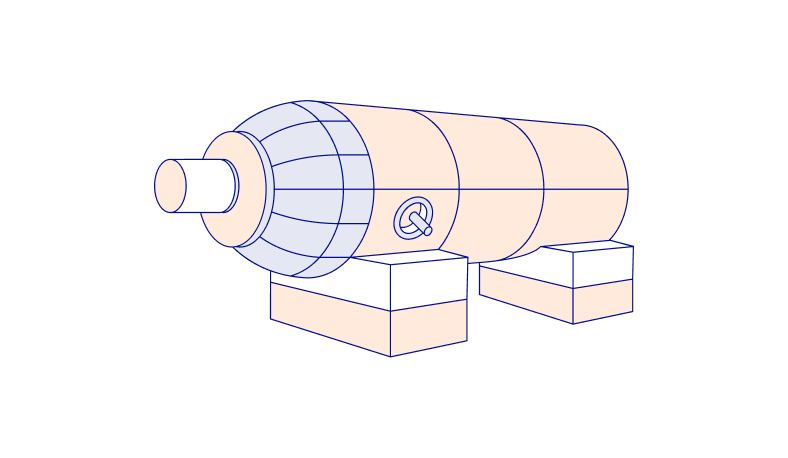

The clean cocoa beans are then broken to loosen the shells from the cocoa nibs. The breaking process takes place in multiple steps to avoid an excess of fine particles.

After the breaking step, what remains is sieved into a number of fractions to reach optimal separation during winnowing. These fractions then go to the winnowing cabinets, where the ‘lighter’, broken shell is removed by a stream of air.

The breaking and winnowing steps separate the essential ingredient of the cocoa beans, the kernel, most often described as the cocoa nib, from its shell.

After the cocoa nibs are separated from the cocoa beans shells, they undergo a sterilization step. The cocoa nibs are sterilized in a batch, or a continuous process, by wetting and heating them with steam. A growing amount of cocoa qualifies, because of the unique nature of its supply chain, as ethically and sustainably sourced. Where applicable, highlighting those aspects can help attract environmentally conscious consumers. After sterilization, the cocoa nib can be roasted directly (natural process), or can be alkalized first (Dutching process).

Alkalizing or Dutching cocoa nibs consists of treating the cocoa nibs with an alkali solution such as potassium or sodium carbonate. It is practised primarily to modify the color and flavor of cocoa powder or cocoa liquor.

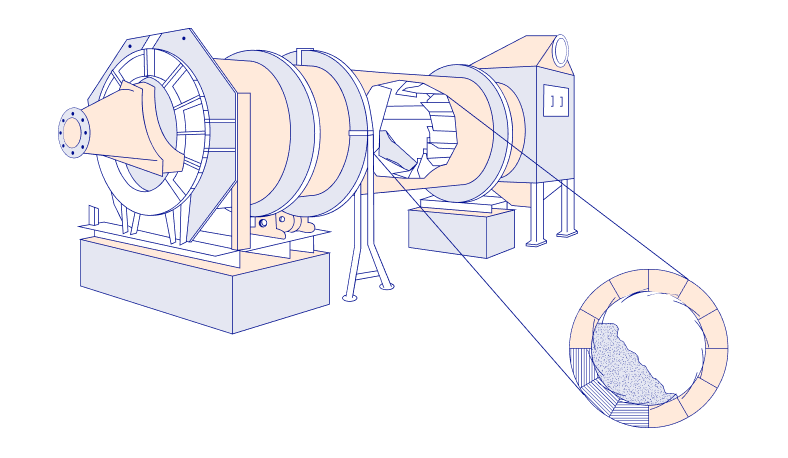

The objectives of the roasting process include reducing the water content and further developing flavor. Roasting is particularly important to solidifying the desired flavor of the cocoa nib because the cocoa nib’s flavor is formed from the precursors that developed during fermentation. Roasting temperatures range from 95-145° C (200-295° F) depending on the process, equipment, type of nib processed, and the end product required.

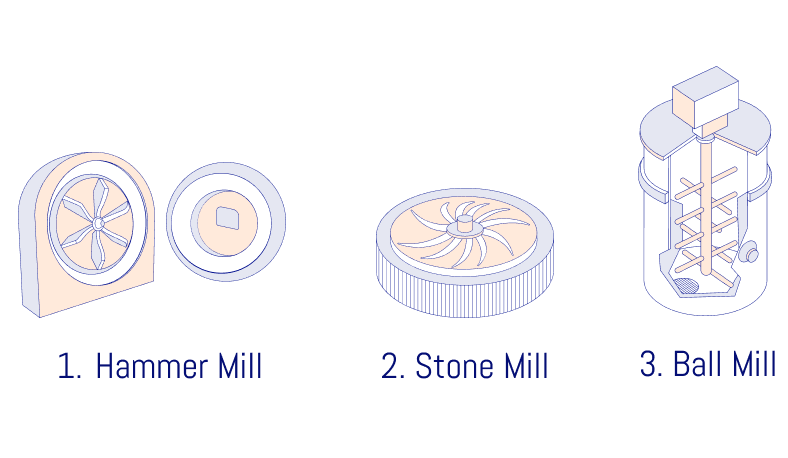

The roasted cocoa nibs are typically ground in a multi-stage process. During grinding, the broken kernels change from a solid to a fluid mass of cocoa particles suspended in cocoa butter. This is due to the high-fat content of the cocoa bean: about half of the nib is fat. Grinding breaks up the cell structure of the cocoa nibs and releases the cocoa butter.

The cocoa nibs are ground using the three-step process illustrated opposite.

Once the cocoa nibs are grounded they transform into a liquid cocoa mass. This finely grounded fluid mass can either be stored in tanks to await pressing, or be shipped and used most often by chocolate manufacturers to further process the chocolate.

The pressing process separates the cocoa mass into two parts, cocoa cake for the production of cocoa powder, and cocoa butter. Cocoa butter constitutes about half the weight of cocoa nibs. This fat is partially removed from the cocoa mass by means of hydraulic presses applying pressures as high as 450 kg/cm2. Depending upon the pressing time and the setting of the press, the resulting cocoa cakes may have a fat content of 10 to 24%.

After pressing, the cakes are broken into kibbled cakes. Kibbled cake is typically stored by fat content and degree of alkalization and may be blended before pulverisation to obtain the desired type of cocoa powder.

The cocoa butter from the presses is filtered and stored. Depending on the desired outcome the cocoa butter can then be partly or wholly deodorised, blended and shipped to manufacturers.

The powder grinding lines pulverise cocoa cake particles into the defined fineness levels. After pulverisation, the powder is cooled so that the fat of the cocoa powder crystallises into its stable form. This helps prevent any discolouration (fat bloom) or lump formation in the bags later, a phenomenon that is caused by insufficient crystallisation of the fat at the moment of filling.

Learn more about black cocoa powder for baked goods and food manufacturing

Find out more